Tec de Monterrey, 2022

Project - Engine Piston Rod Analysis

-Metallography, Failure Mode

THE UNSEEN WEAR INSIDE AN ENGINE

The project set out to answer a critical engineering question: could a piston pin from a small aircraft engine withstand the extreme cyclic stresses of flight, or was it already on the path toward catastrophic failure? Using the tools of failure analysis and prevention, the team combined hands-on laboratory procedures with digital modeling to investigate.

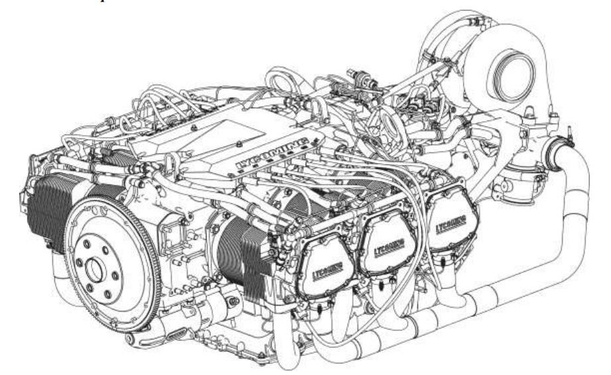

The study focused on the piston pin (bulón) of a Lycoming TEO-540-C1A reciprocating engine, widely used in light aircraft. This steel cylinder connects piston and connecting rod, enduring cyclic compression and bending forces at operating speeds of 2,500–5,000 RPM .

From a theoretical standpoint, several failure mechanisms were possible: fatigue, thermal creep, ductile and brittle fracture, and corrosion cracking. Given the operating environment, this being high temperature and repetitive loading, fatigue was identified as the most likely mode, possibly in combination with thermal damage.

To probe the internal structure, the pin was cut, mounted in resin, polished, and chemically etched for microscopic analysis. Two samples were prepared: one untreated, the other heat-treated. Under the microscope, grain boundaries, voids, and microcracks were revealed. Evidence pointed toward fatigue cracks propagating across the material, while secondary signs of thermal creep cavities appeared along grain boundaries, more evident in the heat-treated specimen. Complementary tests suggested the steel was martensitic stainless steel AISI 420: magnetic, resistant to load and heat, and consistent with the observed microstructure.

Applying Marín’s equations and correction factors (surface finish, size, temperature, load type, and reliability), the team computed:

-

Ultimate tensile strength (assumed): ~600 MPa

-

Corrected endurance limit: ~347 MPa

-

Fatigue resistance: ~557 MPa

-

Factor of safety: ~115

These results indicated that, under normal operating stresses (~4.8 MPa), the piston pin had a very high safety margin. In terms of fatigue life, calculations predicted resistance to more than 10³³ cycles, far beyond practical engine use. Yet the presence of microscopic initiation sites suggested that in-service life could still be limited by local manufacturing defects or heat effects .

A 3D CAD model of the piston pin was created and subjected to static and fatigue simulations in SolidWorks. Results confirmed the experimental findings: the highest stress concentrations occurred at the central section, where the pin interfaces with the connecting rod. Predicted fatigue stress ranged between 4.3 × 10⁸ and 5 × 10⁸ Pa, validating that the center was the most vulnerable region.

The investigation concluded that the piston pin’s primary failure mechanism was fatigue, accelerated by thermal creep. While calculations showed a large safety factor, microscopic defects highlighted the importance of material quality and manufacturing processes.

For preventive maintenance, the report recommended:

-

Oil changes every 50 hours to minimize wear.

-

Microscopic inspections for cracks and corrosion.

-

Dimensional checks of internal and external diameters.

-

Component replacement every ~5000 hours of service, regardless of condition.

Please find attached below the relevant documents to this project. (Note: most, if not all documents, are in Spanish)